Trailer wiring harnesses are crucial for safe towing, but they can encounter various problems that affect their performance and reliability. Understanding these issues is essential for maintaining a safe and efficient towing experience.

In this article, we will explore the common problems that can affect trailer wiring harnesses, as well as preventive measures and maintenance tips to keep them in top condition.

We will also discuss the importance of choosing the right trailer wiring harness for your needs and highlight the benefits of investing in high-quality products.

What is a trailer wiring harness?

A trailer wiring harness is a system of electrical wires, connectors, and plugs that enables a vehicle to communicate with a trailer’s electrical components. It allows the vehicle’s lights, brakes, and other functions to be synchronized with the trailer, ensuring safe and efficient towing.

Trailer wiring harnesses come in various configurations to accommodate different trailer types and electrical systems. They are typically installed by connecting the vehicle’s electrical system to the trailer’s wiring using compatible connectors and plugs.

When properly installed and maintained, a trailer wiring harness can significantly enhance the safety and functionality of towing a trailer.

Common problems affecting trailer wiring harnesses

Corrosion and rust

Corrosion and rust are common issues that can affect trailer wiring harnesses, especially in areas exposed to moisture and harsh environmental conditions. Over time, moisture can seep into connectors and wiring, leading to corrosion and rust formation.

Corroded connectors can cause poor electrical connections, resulting in malfunctioning lights and other electrical components. Rust can also weaken the wiring and connectors, leading to frayed wires and potential short circuits.

To prevent corrosion and rust, it is essential to use high-quality, weatherproof connectors and to regularly inspect and clean the wiring harness. Applying dielectric grease to connectors can also help protect against moisture and corrosion.

Frayed or damaged wires

Frayed or damaged wires are another common problem that can affect trailer wiring harnesses. Wires can become frayed or damaged due to abrasion, excessive heat, or exposure to harsh chemicals. Damaged wires can cause electrical shorts, leading to malfunctioning lights and other electrical components.

To prevent frayed or damaged wires, it is essential to inspect the wiring harness regularly and to replace any damaged or worn-out wires promptly. Using protective sheathing and routing the wiring harness away from hot surfaces can also help prevent damage to the wires.

Loose or corroded connections

Loose or corroded connections can cause poor electrical performance and malfunctioning lights and other electrical components. Loose connections can result from improper installation or wear and tear over time. Corroded connections can occur due to moisture exposure and rust formation.

To prevent loose or corroded connections, it is essential to ensure that all connections are properly tightened and secured. Regularly inspecting and cleaning the connectors and applying dielectric grease can also help prevent corrosion and maintain good electrical performance.

Short circuits

Short circuits can occur when the wiring harness is damaged or improperly installed, causing electrical current to bypass the intended circuit. Short circuits can result in malfunctioning lights and other electrical components, and in some cases, they can cause electrical fires.

To prevent short circuits, it is essential to inspect the wiring harness regularly and to replace any damaged or worn-out wiring. Ensuring that the wiring harness is properly installed and secured can also help prevent short circuits.

Grounding issues

Grounding issues can cause malfunctioning lights and other electrical components in a trailer wiring harness. Poor grounding can result from corroded or loose ground connections, damaged ground wires, or improper grounding techniques.

To prevent grounding issues, it is essential to ensure that all ground connections are properly tightened and secured. Regularly inspecting and cleaning the ground connections and using dedicated ground wires can also help prevent grounding issues.

Preventive measures and maintenance tips

Regular inspections

Regular inspections are essential for maintaining the performance and reliability of a trailer wiring harness. Inspecting the wiring harness for signs of damage, wear, and corrosion can help detect potential issues early and prevent costly repairs. Look for frayed wires, loose or corroded connections, and signs of wear and tear.

Cleaning and maintenance

Cleaning and maintenance are crucial for preventing corrosion and maintaining the integrity of the wiring harness. Use dielectric grease to protect connectors from moisture and corrosion, and clean the wiring harness regularly to remove dirt and debris.

Proper installation

Proper installation is critical for ensuring the safety and reliability of a trailer wiring harness. Follow the manufacturer’s instructions for installation, and ensure that all connections are properly tightened and secured. Use protective sheathing and routing techniques to protect the wiring harness from abrasion, heat, and other environmental factors.

Choosing the right trailer wiring harness

Types of trailer wiring harnesses

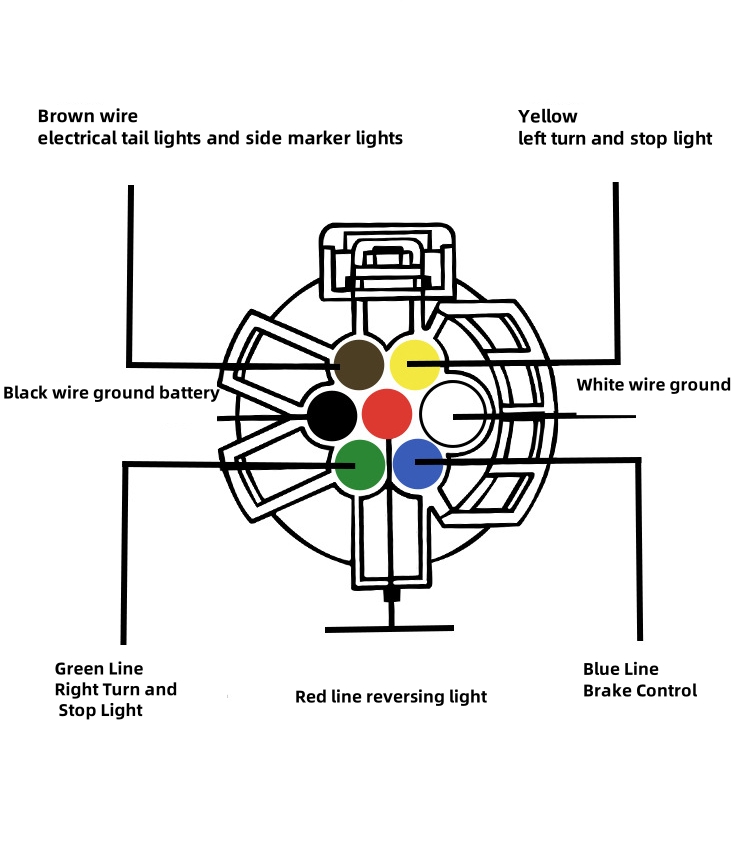

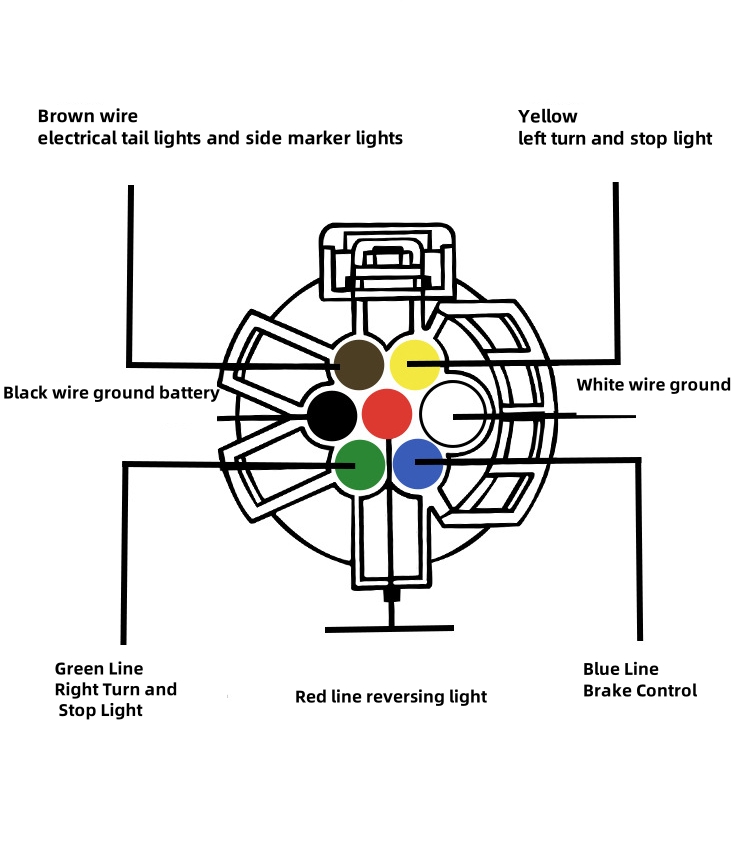

There are several types of trailer wiring harnesses available, each designed for specific trailer types and electrical systems. The most common types include 2-pole, 4-pole, 6-pole, 7-pole, and 9-pole harnesses. Choosing the right type of wiring harness is essential for ensuring compatibility with your vehicle and trailer.

Importance of compatibility

Using a wiring harness that is incompatible with your vehicle and trailer can cause electrical problems and potentially damage your vehicle’s electrical system. It is essential to choose a wiring harness that is specifically designed for your vehicle’s make and model and your trailer’s wiring configuration.

Benefits of high-quality products

Investing in high-quality trailer wiring harnesses and connectors can provide several benefits, including improved reliability, enhanced safety, and reduced maintenance costs. High-quality products are typically more durable and resistant to corrosion and damage, ensuring long-lasting performance and reliability.

Conclusion

Trailer wiring harnesses are critical for safe and efficient towing, but they can encounter various issues that affect their performance and reliability. Common problems include corrosion and rust, frayed or damaged wires, loose or corroded connections, short circuits, and grounding issues.

To prevent these issues and maintain the integrity of your trailer wiring harness, it is essential to perform regular inspections, clean and maintain the wiring harness, and ensure proper installation. Choosing the right trailer wiring harness and investing in high-quality products can also provide several benefits, including improved reliability, enhanced safety, and reduced maintenance costs.