Silicone foam is a versatile and durable material that has gained popularity in various industries due to its exceptional properties. This article will explore the durability of silicone foam in extreme conditions, including its resistance to temperature, moisture, and other harsh environmental factors. We will also discuss the key features that make silicone foam a preferred choice for various applications and provide insights on how to choose the right silicone foam for specific needs.

Silicone foam: an overview

One of the key features of silicone foam is its ability to maintain its properties over a wide temperature range, from -100°F to 500°F. This makes it suitable for use in extreme heat or cold conditions, such as in aerospace, automotive, and industrial applications. Silicone foam also has excellent thermal insulation properties, which helps to reduce energy consumption and improve efficiency.

In addition to its temperature resistance, silicone foam is also highly resistant to moisture, chemicals, and UV radiation. This makes it an ideal choice for use in outdoor applications, such as in construction, roofing, and automotive sealing. Silicone foam is also non-toxic, odorless, and environmentally friendly, making it a safe choice for use in medical and food applications.

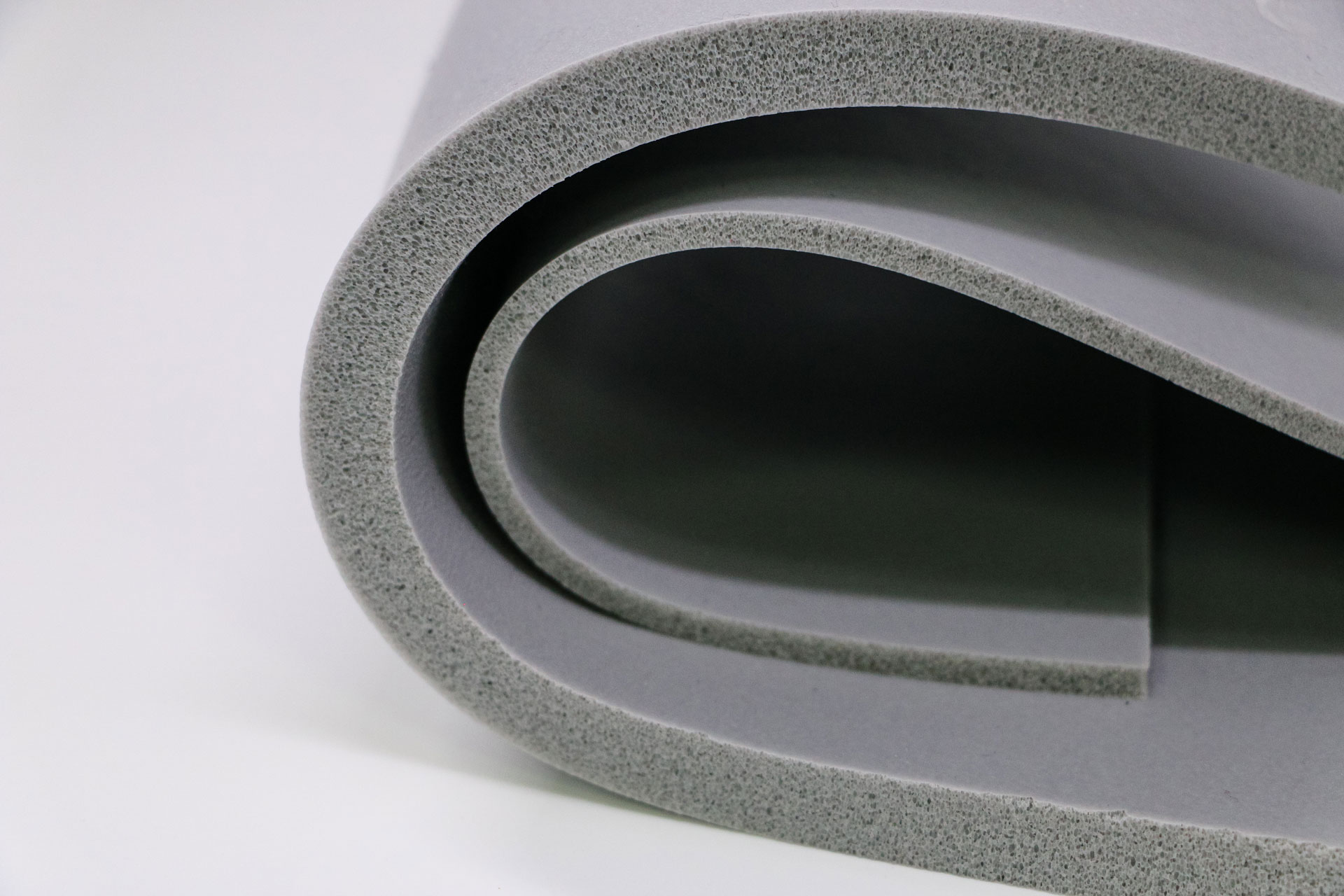

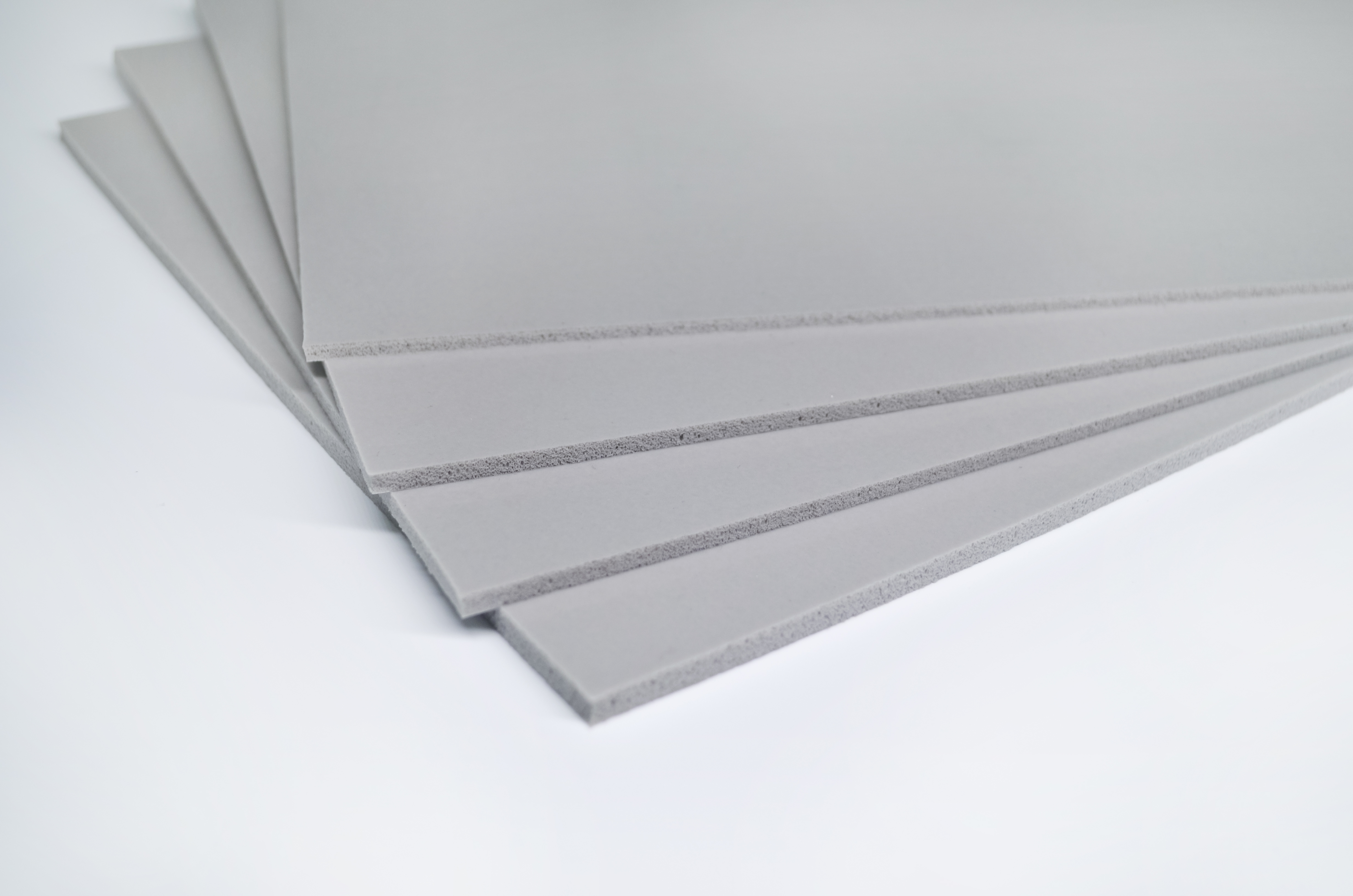

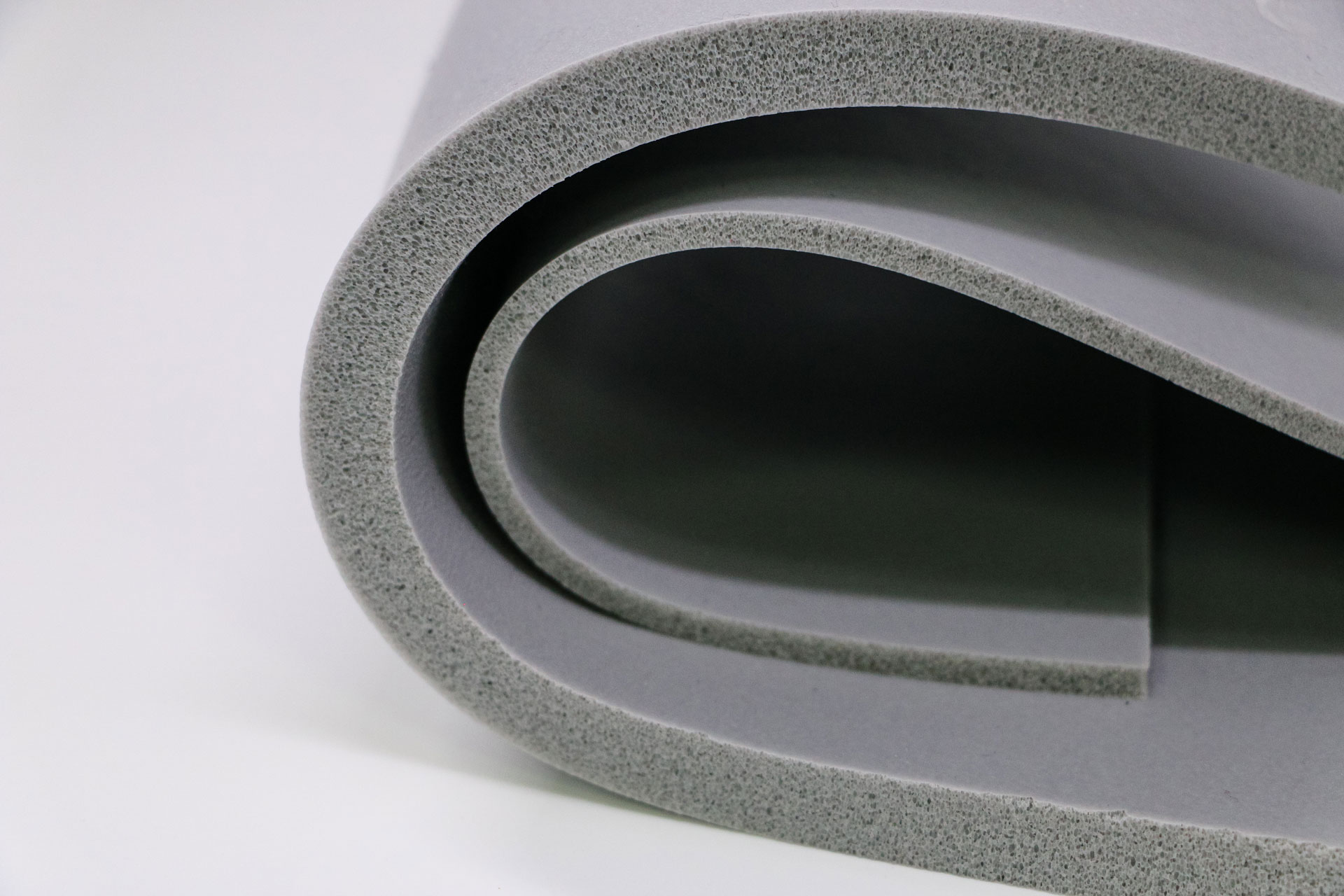

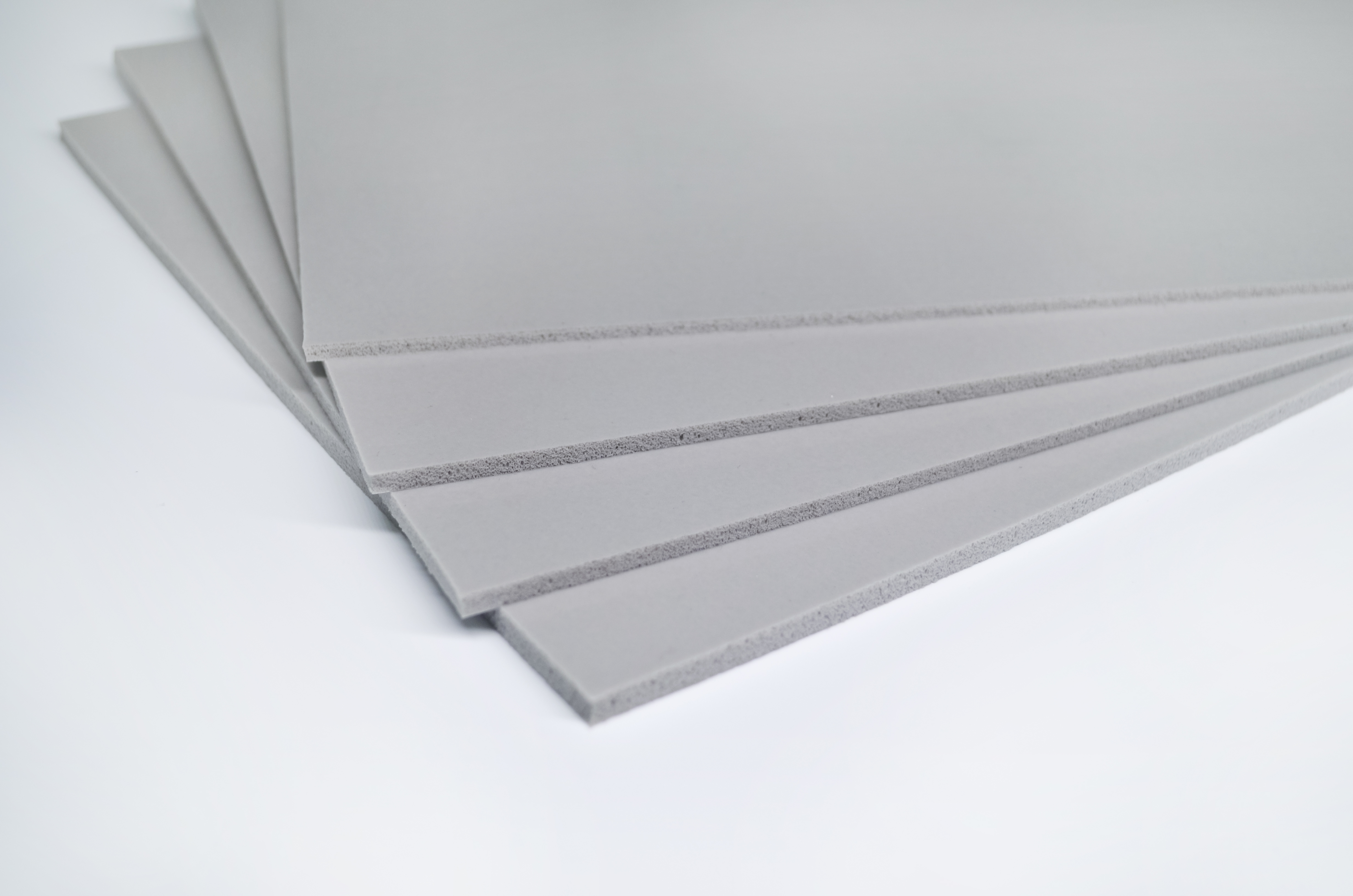

Another key advantage of silicone foam is its flexibility and durability. It can be easily molded into various shapes and sizes, making it suitable for use in a wide range of applications. Silicone foam is also highly resistant to abrasion, compression, and tear, making it a long-lasting and cost-effective solution for various industries.

Overall, silicone foam is a versatile and durable material that offers exceptional resistance to extreme conditions. Its unique properties make it a preferred choice for various applications, including aerospace, automotive, industrial, outdoor, medical, and food applications. With its ability to maintain its properties over a wide temperature range, resistance to moisture, chemicals, and UV radiation, and flexibility and durability, silicone foam is a reliable and cost-effective solution for various industries.

Factors affecting durability

Several factors can affect the durability of silicone foam in extreme conditions. One of the primary factors is the quality of the silicone used in the manufacturing process. High-quality silicone is essential for ensuring that the foam maintains its properties over time. Poor-quality silicone can lead to degradation, brittleness, and loss of elasticity, which can compromise the durability of the foam.

Another factor that can affect the durability of silicone foam is the manufacturing process itself. The use of additives, fillers, or other materials during the manufacturing process can impact the properties of the foam. For example, the addition of certain fillers can improve the foam’s resistance to abrasion and compression, while the use of low-quality additives can lead to discoloration, degradation, and loss of mechanical properties over time.

The environmental conditions in which the silicone foam is used can also impact its durability. Exposure to extreme temperatures, moisture, UV radiation, chemicals, or other harsh environmental factors can cause the foam to degrade over time. For example, prolonged exposure to high temperatures can cause the foam to lose its elasticity and become brittle, while exposure to moisture can cause the foam to absorb water and lose its insulating properties.

To ensure the durability of silicone foam in extreme conditions, it is essential to choose high-quality silicone foam that is specifically designed for the intended application. It is also important to consider the environmental conditions in which the foam will be used and choose a foam with the appropriate properties to withstand those conditions. Proper installation and maintenance can also play a crucial role in ensuring the longevity and durability of silicone foam in extreme conditions.

Applications of silicone foam

Silicone foam is a versatile material that is used in a wide range of applications across various industries. Its unique properties make it an ideal choice for applications that require resistance to extreme temperatures, moisture, chemicals, and UV radiation. Here are some of the most common applications of silicone foam:

One of the primary applications of silicone foam is in the aerospace industry. Silicone foam is used in aircraft insulation, gaskets, seals, and other components that are exposed to extreme temperatures and harsh environmental conditions. Its ability to withstand extreme temperatures and resist moisture and chemicals makes it an ideal choice for aerospace applications.

Silicone foam is also widely used in the automotive industry for various applications, including weather stripping, gaskets, seals, and interior components. Its resistance to extreme temperatures, moisture, and UV radiation makes it an ideal choice for automotive applications, where components are exposed to harsh environmental conditions.

In the industrial sector, silicone foam is used for insulation, gaskets, seals, and other applications that require resistance to extreme temperatures, moisture, and chemicals. Its durability and flexibility make it an ideal choice for industrial applications, where components are exposed to harsh environmental conditions and require long-lasting performance.

Silicone foam is also used in the construction industry for insulation, roofing, and sealing applications. Its resistance to extreme temperatures, moisture, and UV radiation makes it an ideal choice for construction applications, where components are exposed to harsh environmental conditions and require long-lasting performance.

In the medical industry, silicone foam is used for various applications, including prosthetics, implants, and wound care. Its biocompatibility, non-toxicity, and resistance to extreme temperatures make it an ideal choice for medical applications, where components are exposed to harsh environmental conditions and require long-lasting performance.

Overall, silicone foam is a versatile material that is used in a wide range of applications across various industries. Its unique properties make it an ideal choice for applications that require resistance to extreme temperatures, moisture, chemicals, and UV radiation. With its durability, flexibility, and long-lasting performance, silicone foam is a reliable and cost-effective solution for various industries.

Conclusion

Silicone foam is a versatile and durable material that offers exceptional resistance to extreme conditions. Its unique properties, including resistance to extreme temperatures, moisture, chemicals, and UV radiation, make it an ideal choice for various applications across multiple industries. When choosing silicone foam, it is essential to consider factors such as the quality of the silicone, the manufacturing process, and the environmental conditions in which the foam will be used. By selecting high-quality silicone foam and following proper installation and maintenance practices, businesses can ensure the durability and longevity of silicone foam in extreme conditions.