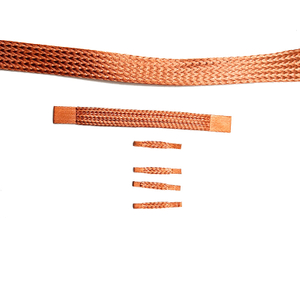

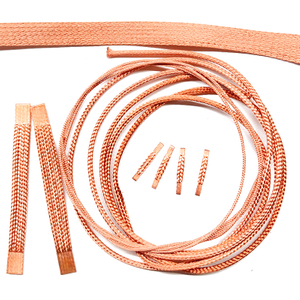

High-Quality Copper Wire Braids: Reliable Braided Copper Conductors for Various Applications

Key Features

Superior Conductivity: Made from high-purity copper for excellent electrical conductivity.

Durable and Flexible: Designed to withstand mechanical stress and provide flexibility in installation.

Versatile Applications: Ideal for grounding, shielding, and power distribution in various industries.

Corrosion Resistance: Resistant to corrosion, ensuring long-lasting performance.

Custom Sizes Available: Available in various widths and lengths to meet specific requirements.

Specifications

| Property | Details |

| Material | High-purity copper |

| Width | Customizable (standard: 1/4 inch to 2 inches) |

| Length | Custom lengths available |

| Stranding | Multiple stranding options for flexibility |

| Temperature Range | -55°C to 150°C |

| Compliance | Meets industry standards for quality and safety |

Applications

Our Copper Wire Braids are perfect for:

Electrical Grounding: Providing reliable grounding in electrical systems.

EMI/RFI Shielding: Effective in shielding electronic devices from electromagnetic and radio frequency interference.

Power Distribution: Used in power cables and busbars for efficient power distribution.

Automotive: Ideal for use in automotive electrical systems for grounding and shielding.

Telecommunications: Ensuring stable connections in telecom equipment.

What is the main function of metal braiding?

What is metal braiding?

Metal braiding is a protective covering layer for wires and cables. It is a mesh structure formed by a certain number and specification of metal wires or tapes twisted together, covering the insulation layer of the cable or the outside of the cable core. The metal braiding can enhance the mechanical strength of the cable, improve the anti-interference ability of the cable, and protect the cable from external damage or influence.

Types and characteristics of metal braiding

There are two main types of metal braiding: copper wire braiding and steel wire (iron wire) braiding. Their characteristics are as follows:

Copper wire braiding

It is composed of copper wire or tinned copper wire, with good conductivity and softness. It can be used as the total shield or single-core shield of the cable, or as a grounding wire for safety protection. Copper wire braiding is generally used for control cables, communication cables, high-voltage cables, etc.

Steel wire (iron wire) braiding

It is composed of steel wire or iron wire, with high mechanical strength and wear resistance. It can be used as mechanical protection of the cable or withstand longitudinal tension, or as a magnetic field shield. Steel wire (iron wire) braided layer is generally used for marine cables, marine cables, mining cables, etc.

The role of metal braided layer

The role of metal braided layer mainly includes the following aspects:

Mechanical protection

The metal braided layer can increase the mechanical strength of the cable, prevent the cable from being damaged or scratched by external forces during installation, transportation and use, and extend the service life of the cable.

Shielding interference

The metal braided layer can effectively isolate the external electromagnetic interference or magnetic field interference, ensure the stable transmission of the internal signal of the cable, and improve the signal quality of the cable.

Eliminate induction

The metal braided layer can eliminate the induced potential generated on the surface of the power cable, reduce the induction loss and leakage current, and improve the efficiency and safety of the cable.

Safety protection

The metal braided layer can be used as a grounding wire or leakage detection wire to promptly reflect whether there is leakage or short circuit in the cable, and prevent accidents such as electric shock or fire.

Advantages of metal braided layer

Simple structure

The metal braided layer only needs to cross-twist a certain number and specification of metal wires or belts in a certain way, without the need for complex processes and equipment.

Low cost

The material cost and processing cost of the metal braided layer are relatively low, which can save the production cost of the cable.

Reliable performance

The performance of the metal braided layer is stable, and it is not easily affected by environmental factors such as temperature, humidity, and chemicals, and can maintain a good working condition for a long time.

Precautions for metal braided layer

The precautions for metal braided layer mainly include the following aspects:

- Select the appropriate type and specification of metal braided layer, and select the appropriate copper wire or steel wire (iron wire) braided layer according to the purpose and environmental requirements of the cable, as well as the appropriate braiding density and coverage.

- Check the quality and integrity of the metal braided layer, avoid using metal braided layers with defects such as oxidation, rust, breakage, looseness, etc., and ensure that the metal braided layer is tightly combined with other parts of the cable without gaps or cracks.

- Pay attention to protecting the metal braided layer during installation to avoid damage or deformation of the metal braided layer during installation, which will affect its performance and effect.

Disadvantages of metal braided layer

- Increase the weight and volume of the cable, reduce the softness and bendability of the cable, and increase the difficulty and cost of cable installation.

- It is susceptible to corrosion or oxidation, which affects the life and appearance of the cable and requires regular cleaning and maintenance.

- It is easy to generate contact resistance or grounding resistance, which affects the conductivity and safety performance of the cable. Attention should be paid to the treatment of grounding or joints.