Tin-copper is a commonly used alloy that has a variety of applications in the automotive industry.

Electrical connectors: Tin-copper alloys are widely used in the manufacture of automotive electrical connectors due to their good electrical conductivity and solderability. Electrical connectors play a key role in automobiles, connecting different electrical components and systems to ensure the reliability and stability of current transmission.

Engine components: Tin-copper alloys are widely used in automotive engines. For example, tin-copper alloys are often used in the manufacture of piston rings and cylinder gaskets because they have good thermal conductivity and high-temperature resistance, and are able to withstand the pressure and friction of high-temperature engine environments.

Braking systems: Tin-copper alloys are used in automotive braking systems to make brake discs and pads. This is because tin-copper alloys have excellent thermal conductivity and abrasion resistance, which enables them to dissipate heat quickly during braking and provide stable and reliable braking effects.

Radiators: Tin-copper alloys are also commonly used in the manufacture of automotive radiators. The radiator is a key component of the automotive cooling system and is used to dissipate heat generated by the engine. Tin-copper alloys have good thermal conductivity, which helps to dissipate heat efficiently and maintain the normal operating temperature of the engine.

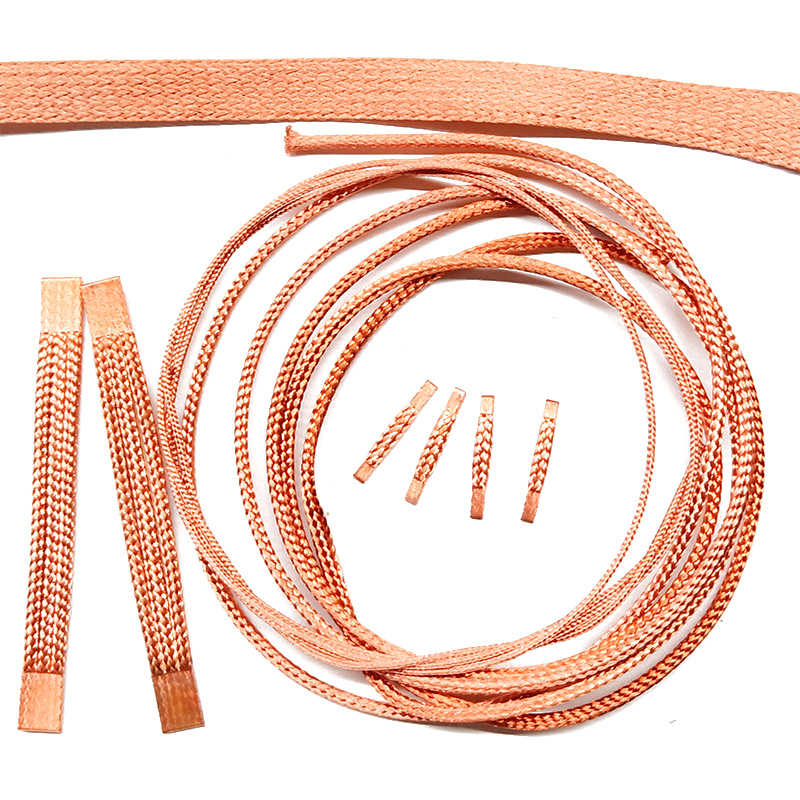

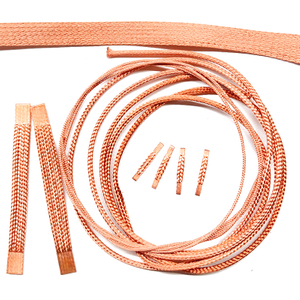

Grounding systems: Grounding systems in automobiles require good conductivity and corrosion resistance. Tin-copper alloys are commonly used in the manufacture of grounding wires and connectors to ensure reliable grounding of electrical currents and to minimize electrical faults and interference.

In summary, tin-copper has a wide range of applications in the automotive industry, including electrical connectors, engine components, braking systems, radiators and grounding systems. Its excellent conductivity, abrasion resistance, heat resistance and heat transfer properties make it an ideal choice for many critical automotive components.

Welcome to contact us for more details

Braided Copper Wire Production Lines:

Braided Copper Products