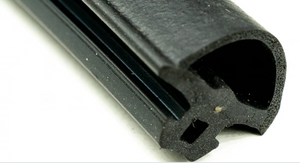

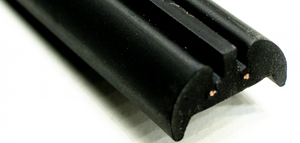

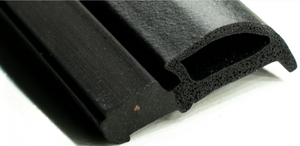

EPDM (Ethylene Propylene Diene Monomer):EPDM is renowned for its excellent weathering, ozone, and UV resistance, making it ideal for outdoor and high-temperature applications.

It is also highly resistant to water, steam, and certain chemicals.

Applications: Automotive seals, weatherstrips, industrial gaskets, and HVAC systems.

Benefits: Exceptional durability, temperature resistance, and weatherproof properties.

NBR (Nitrile Butadiene Rubber):NBR offers excellent resistance to oils, fuels, and other chemicals, making it the go-to material for applications that involve contact with petroleum-based fluids.

Applications: Fuel hoses, gaskets, seals, and oil-resistant components.

Benefits: High resistance to oil, fuel, and wear, with good mechanical properties.

CR (Chloroprene Rubber, also known as Neoprene):CR is known for its balanced combination of durability, weather resistance, and flame retardancy. It also has good resistance to oils,

chemicals, and ozone.

Applications: Electrical insulation, automotive seals, hoses, and belts.

Benefits: Great resistance to weather, oil, and aging, with strong flame-retardant properties.

Silicone Rubber:Silicone is a versatile material that offers excellent flexibility, thermal stability, and resistance to extreme temperatures, making it perfect for applications requiring high heat tolerance and electrical insulation.

Applications: Gaskets, seals, and medical components, as well as parts used in high-temperature environments.

Benefits: High temperature resistance, flexibility, and biocompatibility.

Custom Manufacturing for Specific Needs: Every rubber component we produce is customized to fit perfectly in its function for industrial applications, from seals and gaskets to cushioning pads,

through our customized molding process ensuring superior quality in every instance.

Durability and Resistance:Our molded rubber parts are built to withstand harsh environments, providing outstanding resistance against heat, chemicals, oils, UV exposure and extreme temperatures.

Even when exposed to chemicals that corrode components over time, these components continue to operate effectively and securely over time.

Wide Range of Applications:Our custom rubber components serve a range of industries - from automotive and aerospace to industrial machinery and electrical systems. By tailoring each part to meet

individual use cases, our components ensure optimal results for our clients.

Flexible Manufacturing Capabilities:We provide flexible production runs from small batches to larger orders, meeting both your project deadlines and volume requirements without compromising quality.

Precision Engineering and Quality Control:Our state-of-the-art molding facilities and stringent quality control processes guarantee that each component is crafted to exacting standards. Each batch

undergoes stringent tests for mechanical properties, temperature resistance and material integrity - meeting industry standards in terms of both durability and functionality.

Experience in Custom Molding: With years of expertise in rubber molding, we specialize in the design, prototyping and production of custom rubber parts that meet all industry and technical specifications.

Our team works closely with each client to make sure every component meets their technical requirements and industry requirements.

Innovative Solutions for Every Industry:From automotive to aerospace, our custom molded rubber solutions help enhance performance and reliability across a range of industries.

Eco-Friendly and Sustainable Manufacturing: At our facility, we are dedicated to sustainability. All materials used and production processes adhere to environmental regulations such as RoHS and REACH standards,

providing eco-friendly production.

Fast Turnaround Times and Competitive Pricing: At Custom Molded Rubber Components Inc, we understand the importance of meeting tight project deadlines without compromising on quality, and offer fast

turnaround times without compromising. Furthermore, our competitive pricing ensures you receive maximum value for custom-molded rubber components with high performance capabilities.