Silicone foam is a versatile material with a wide range of applications, from industrial uses to consumer products. This article will explore the manufacturing process of silicone foam, including the materials and techniques used, as well as the benefits and drawbacks of this material. By the end, readers will have a better understanding of how silicone foam is made and what makes it a valuable material for various industries.

Silicone foam manufacturing process

Silicone foam is a versatile material that is used in a variety of industries, including automotive, aerospace, medical, and consumer products. The manufacturing process for silicone foam involves several steps, each of which is critical to producing a high-quality product. In this section, we will explore the various steps involved in the manufacturing process of silicone foam.

Material selection

The first step in the manufacturing process of silicone foam is material selection. Silicone foam is made from silicone rubber, which is a synthetic elastomer that is known for its durability and resistance to extreme temperatures. Silicone rubber is available in two forms: liquid silicone rubber (LSR) and room temperature vulcanized (RTV) silicone rubber. LSR is a two-part system that requires heat to cure, while RTV silicone rubber cures at room temperature.

Mixing

The next step in the manufacturing process of silicone foam is mixing. The silicone rubber is mixed with a curing agent, which causes the silicone to harden and form a solid mass. The curing agent is typically added in small amounts, as too much can cause the silicone to cure too quickly and become brittle.

Foaming agent addition

After the silicone rubber and curing agent have been mixed, a foaming agent is added to the mixture. The foaming agent is typically a gas, such as nitrogen or air, that is introduced into the silicone mixture under high pressure. The gas expands and creates a cellular structure within the silicone, resulting in the formation of foam.

Foam formation

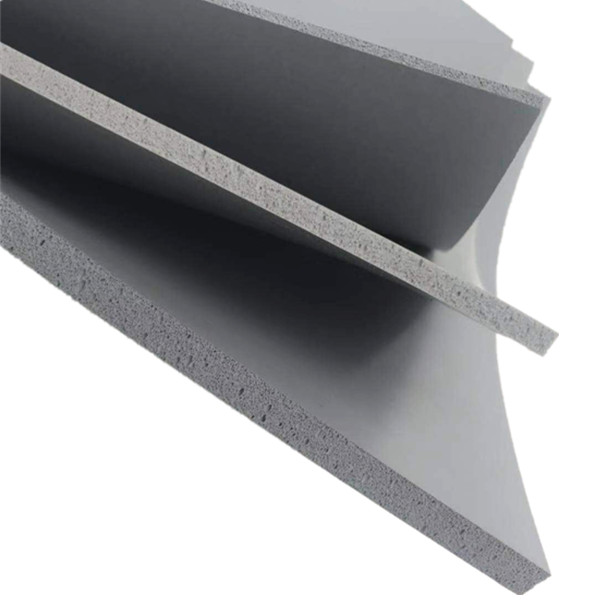

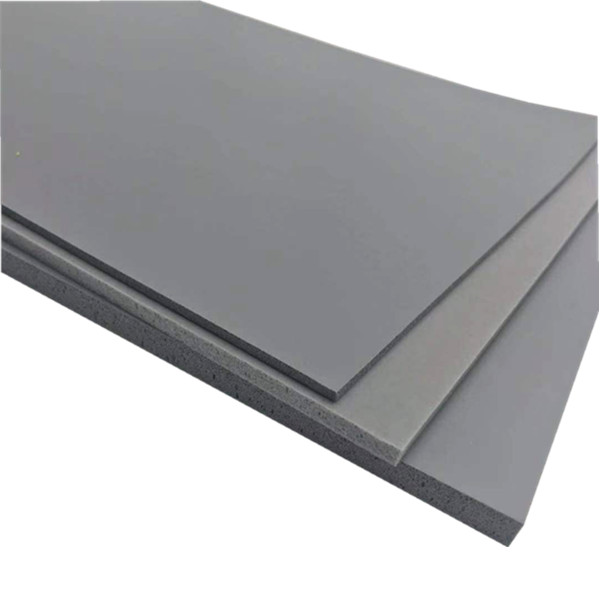

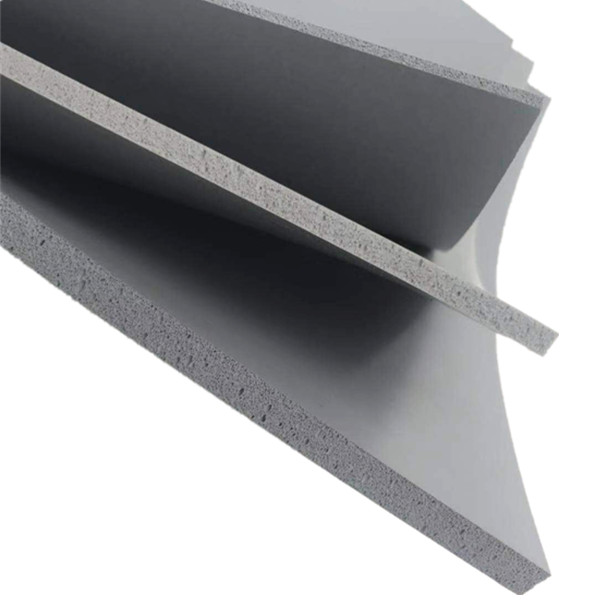

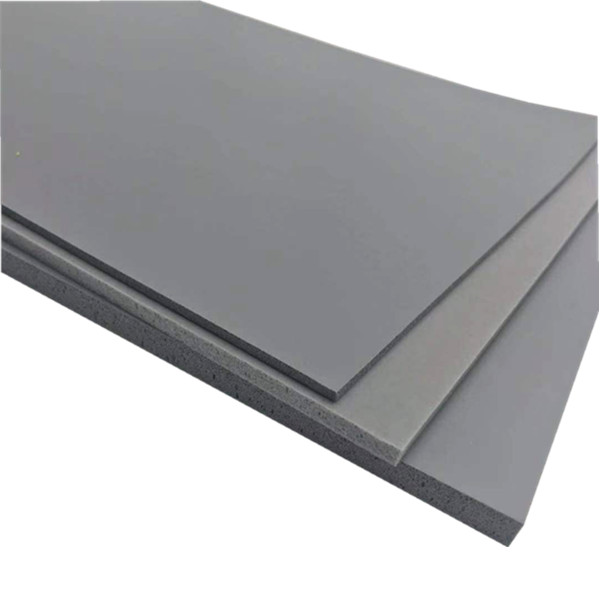

The next step in the manufacturing process of silicone foam is foam formation. The silicone mixture is poured into a mold, where it is allowed to expand and cure. The mold is typically made of a material that is easy to release, such as silicone or Teflon. Once the foam has cured, it is removed from the mold and can be cut or shaped to meet the desired specifications.

Cutting and shaping

After the foam has been formed, it is cut and shaped to meet the desired specifications. This can be done using a variety of methods, such as die cutting, waterjet cutting, or CNC machining. The foam can be cut into sheets, rolls, or custom shapes, depending on the application.

Quality control

The final step in the manufacturing process of silicone foam is quality control. The foam is inspected for defects, such as air pockets, uneven density, or improper curing. Samples may be taken for testing to ensure that the foam meets the required specifications, such as density, tensile strength, and elongation.

Applications of silicone foam

Silicone foam is a versatile material that has a wide range of applications in various industries. Its unique properties, such as resistance to extreme temperatures, chemicals, and UV radiation, make it an ideal material for many applications.

One of the most common applications of silicone foam is in the automotive industry. Silicone foam is used as a gasket material to seal engine components, such as valve covers and oil pans. Its resistance to high temperatures and chemicals makes it an ideal material for this application.

Silicone foam is also used in the aerospace industry to insulate and protect sensitive electronic components. Its lightweight and flexible properties make it an ideal material for this application, as it can conform to the shape of the components and provide excellent insulation.

In the medical industry, silicone foam is used to make prosthetics and orthotics. Its biocompatibility and resistance to bacteria make it an ideal material for this application, as it can be used to create custom-fit prosthetics that are comfortable and safe for the patient.

Silicone foam is also used in the consumer products industry to make products such as mattresses, pillows, and seat cushions. Its softness and durability make it an ideal material for these applications, as it can provide excellent support and comfort.

In addition to these applications, silicone foam is also used in the construction industry as an insulation material. Its resistance to extreme temperatures and fire makes it an ideal material for insulating pipes, walls, and roofs.

Overall, silicone foam is a versatile material that has a wide range of applications in various industries. Its unique properties make it an ideal material for many applications, and its popularity is only expected to increase in the future.

Conclusion

Silicone foam is a versatile and valuable material that is used in a wide range of industries. Its unique properties, such as resistance to extreme temperatures, chemicals, and UV radiation, make it an ideal material for many applications. The manufacturing process for silicone foam involves several steps, including material selection, mixing, foaming agent addition, foam formation, cutting and shaping, and quality control. Overall, silicone foam is a valuable material that is expected to continue to be used in a variety of applications in the future.